Direct-to-film (DTF) printing, with its cutting-edge technique, offers unparalleled quality and speed in image reproduction. This method bypasses traditional intermediate surfaces, delivering vibrant, detailed prints suitable for various applications from art to film graphics. Expedited DTF services, leveraging advanced technologies, revolutionize the industry by compressing production times without sacrificing quality, enabling quicker design iterations and faster market releases. Choosing a reputable provider with expertise in handling high-speed jobs, specific formats, and maintaining accuracy under tight deadlines ensures successful DTF printing projects.

In today’s fast-paced media landscape, direct-to-film (DTF) transfers offer a cutting-edge solution for print-on-demand services. This innovative process streamlines production by printing directly onto film without intermediate stages. Expedited production services play a pivotal role in enhancing DTF printing efficiency. By leveraging accelerated workflows, these services ensure timely delivery of high-quality film prints, catering to the demanding needs of modern businesses. Discover how optimized DTF printing can revolutionize your operations.

- Understanding Direct-to-Film Transfers: A Brief Overview

- The Role of Expedited Production Services in DTF Printing

- Benefits of Using Accelerated Production for Film Printers

- Key Considerations when Choosing an Expedited Service Provider

- Technical Aspects of Efficient DTF Printing Processes

- Case Studies: Successful Implementation of Expedited DTF Printing

Understanding Direct-to-Film Transfers: A Brief Overview

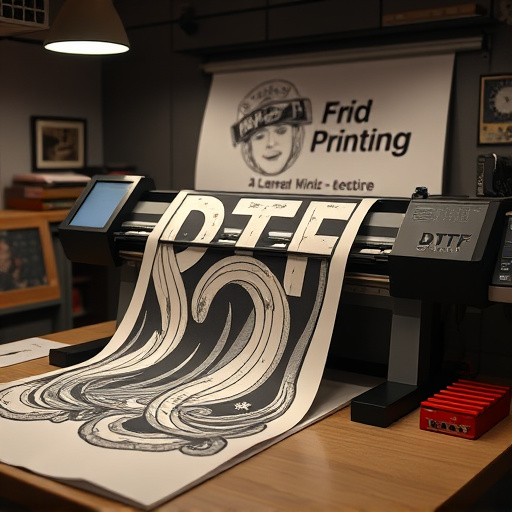

Direct-to-film (DTF) transfers are a cutting-edge printing technique revolutionizing the way we reproduce images and art. This method involves directly transferring ink onto film, bypassing traditional intermediate surfaces, resulting in incredibly detailed and vibrant prints. DTF Printing offers a game-changer for artists and photographers, enabling them to create high-quality, large-format reproductions with exceptional color accuracy.

By eliminating the need for complex processes, DTF transfers streamline production, making it an expedited service ideal for various applications. Whether it’s creating art exhibitions, printing promotional banners, or producing custom graphics for films, this technology ensures a fast turnaround time without compromising on quality.

The Role of Expedited Production Services in DTF Printing

In the realm of direct-to-film (DTF) printing, expedited production services play a pivotal role in streamlining the process and ensuring timely delivery. These specialized services are designed to cater to the unique demands of DTF, where speed and precision are paramount. By leveraging advanced technologies and optimized workflows, expediting production houses significantly reduce turnaround times without compromising on quality.

For DTF Printing enthusiasts and professionals, this means faster access to prints, enabling them to iterate more quickly, test different designs, and bring their creative visions to life promptly. Expedited services also facilitate bulk orders, catering to the needs of businesses and artists looking to produce large batches without the usual delays. This efficiency is particularly crucial in today’s fast-paced market where speed to market is a key differentiator.

Benefits of Using Accelerated Production for Film Printers

Using accelerated production services for direct-to-film (DTF) printing offers numerous advantages that can significantly enhance the film industry’s efficiency and quality standards. One of the key benefits is speed; these advanced production techniques enable faster turnaround times, ensuring filmmakers can swiftly get their projects from concept to screen. This is especially crucial in the fast-paced entertainment sector where deadlines are tight and schedules demanding.

Additionally, accelerated production methods often lead to improved consistency and precision in film printing. With specialized equipment and expertise, technicians can produce high-quality prints with precise color accuracy, ensuring the vision of the filmmakers is faithfully represented on screen. This level of quality control is vital for maintaining the artistic integrity of films during the transfer process.

Key Considerations when Choosing an Expedited Service Provider

When selecting an expedited service provider for direct-to-film (DTF) printing, several crucial factors come into play. Firstly, consider their expertise and experience in handling high-speed printing jobs, as this ensures consistent quality even under tight deadlines. The capability to accommodate your specific film format and resolution requirements is essential, ensuring the final print matches your vision. Reputable service providers will have advanced equipment and a team skilled in managing rapid production without sacrificing accuracy or detail.

Another key consideration is their turnaround time and ability to meet stringent deadlines. Reliable providers offer expedited services without compromising on quality, which is vital for projects with strict timelines. Additionally, check their customer support and communication; prompt responses and transparent updates during the printing process can significantly enhance your overall experience.

Technical Aspects of Efficient DTF Printing Processes

The technical intricacies of Direct-to-Film (DTF) printing processes play a pivotal role in ensuring efficient and high-quality production. This method involves precisely transferring ink directly onto various substrates, requiring meticulous control over several variables. Key aspects include ink formulation, where specialized DTF inks are designed to offer vibrant colors, excellent adhesion, and fast drying times, all crucial for maintaining image integrity during the printing and curing stages.

Moreover, equipment calibration and maintenance are essential. Advanced printers equipped with high-resolution nozzles and precise mechanical systems enable accurate drop placement and consistent print quality. Optimal settings for temperature, pressure, and cure time guarantee that the ink fuses seamlessly with the substrate, resulting in durable prints suitable for various applications. Regular servicing ensures these machines operate at peak performance, thereby streamlining production workflows and meeting tight deadlines for direct-to-film transfers.

Case Studies: Successful Implementation of Expedited DTF Printing

In recent years, there have been numerous successful implementations of expedited DTF (Direct-to-Film) printing services across various industries. These case studies highlight the benefits and efficiency gains that can be achieved through accelerated production processes tailored for DTF Printing. For instance, in the retail sector, one leading apparel brand streamlined its product launch timeline by leveraging expedited DTF Printing. This allowed them to quickly produce small batches of custom designs, enabling rapid market testing without incurring high set-up costs.

Moreover, media and entertainment companies have also reaped significant advantages. A major film studio utilized expedited DTF Printing for generating high-quality promotional materials during the pre-production phase. By accelerating the printing process, they were able to meet tight deadlines, ensuring that marketing campaigns aligned perfectly with production milestones. These success stories underscore the versatility and speed of DTF Printing when combined with efficient production services, opening up new possibilities for businesses seeking agile manufacturing solutions.